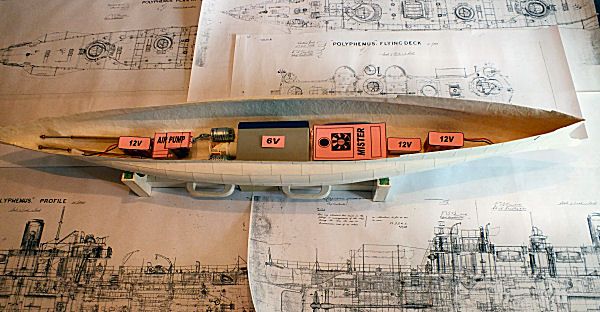

Layout of internals:I have found from previous builds that it is best to organise the internal layout before fitting bulkheads etc. There is a lot going into this hull. Murphy’s Law dictated that I am going to have to alter the ballast tank profiles to get vertical side walls with 100 mm between to fit the 6V 12AH SLA battery between, and allow space for the shafts and motors. I was hoping that the mister outlet could be directly under the funnel, but . . .

Batteries

BatteriesThree battery sets involved. A big 6V 12Ah SLA for the low RPM motors, 12V for the air pump, and 24V for the mister. For the later I have two 12V NiMh packs in series as it only needs around 1/2A for several hours running. The 12V for the pump that Andy recommended (now on order) can also be fairly small. Batteries as low in the hull as possible, final positions will be adjusted by bath-test ballasting, but will require waterproof cable glands between compartments.

ElectronicsThe electronics modules will be mounted on a removable internal panel, keeping them well away from motors and pump etc. Mounting the 2.5” mylar cone speaker will need some thought due to very low freeboard.

I aim to operate the ballasting controls from one channel (stick). A chunky servo sits at neutral. Operate one way rudder-type linkages will open the Blagdon air valves, and in the other direction a cam + microswitch will turn on the air pump.

That should be interesting !

Author

Topic: Bob's H.M.S. Polyphemus (Read 263605 times)

Author

Topic: Bob's H.M.S. Polyphemus (Read 263605 times)