Right. let's try this again.

If you didn't want to see the build, there was not a need to wipe every-bodies post for a whole week.

This is it, my way of building the Model Slipway Assurance class tug.

I’m not building this as a replica of any particular boat, for the most it will be built as per instructions with the kit parts. But some modifications will be made along the way, purely for physical appearance to my liking. Not fully planned all the paint colours yet, but will be done to my own personal preference.

Hopefully, at the end, it will be a reasonable looking and working tug.

I picked the kit up with a few bits already started, including a fitted bow thruster. I had plans to fit a bow thruster myself anyhow, just saved me the trouble. The rudder and prop shaft had also been fitted.

I started this kit about four weeks ago, but did take pictures of most of the progress. So the first few posts are going to be what already has been achieved.

So, on to what has been done.

The fitted original rudder.

Now, I want a rudder that is removable. So the first thing was to cut the old rudder out, leaving the bottom support in place.

Next, was to remove the original top rudder support.

A bit of brass tube was then refitted in a wooden block for the top rudder support, aligning with the hole in the original bottom support.

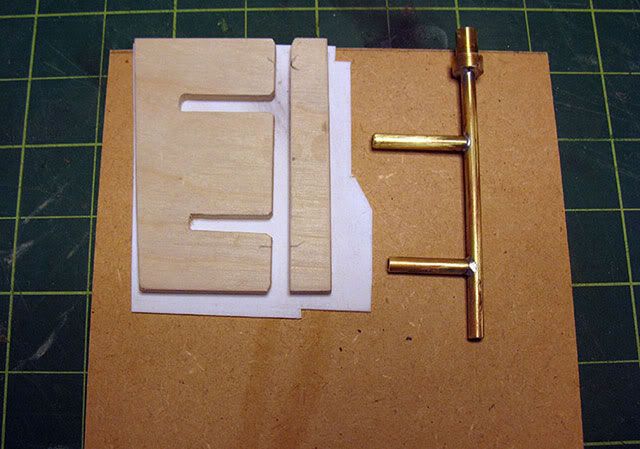

I then made a new rudder from 4mm ply, covered with 1mm plastic sheet. A piece of brass tube with an old splined coupling (turned down) silver soldered to the brass tube was sandwiched into the rudder assembly.

A stainless steel rod was dropped in from the top and the rudder secured to the rod via the grub screw in the old coupling.

One removable rudder.

Cheers

Alan……………

Author

Topic: Assurance Class Tug - Model Slipway - Build (Read 19964 times)

Author

Topic: Assurance Class Tug - Model Slipway - Build (Read 19964 times)