Hi all,

I have been recording the build of my TVR1A steam plant on another thread here ("Oh no, not another TVR1A!"), and have just embarked on the build of the boat that it will power (I hope!). I have bought a Solent steam launch hull from Models by Design, and this is what you get when you take it out of the packaging (although the simple stand is my own concoction, not part of the deal). I should say straight away that my choice of hull was influenced heavily by Andy Wright's lovely build here

http://www.modelboatmayhem.co.uk/forum/index.php?topic=3755.msg49829#msg49829 and if mine turns out half as good as his I'll be well pleased.

You also get a full size drawing of the side and top elevations of the finished boat with some construction suggestions, although the dimensions of the drawing don't exactly match the moulding. This isn't a particular problem - I find the drawing very useful for planning and doodling, but all measurements need to be taken from the actual hull. The hull is nominally 1/8 scale, which fits pretty well with my engine and boiler (for example, the boiler is 6" long, which would make it 4 feet at full size - sounds about right for a small boiler).

I decided that I wasn't all that keen on the deck moulding. Nothing wrong with the moulding itself, but I didn't take to the way the cockpit narrows in the forward part and I have decided to build a wooden deck straight onto the hull. This also allows me to make more room for the steam plant - the drawing shows a vertical boiler, while I have a horizontal one and this obviously takes up a little more space.

My first alteration was purely cosmetic; with a wood deck, I wanted a wood stem showing above the bow. This meant removing part of the moulding and inserting a wooden replacement. This only had to be enough to show above the deck, as the hull will be painted, so I only removed enough to give my wood insert a good gluing surface. Here's the original bow with my cut lines marked -

and here's the section cut out -

I am undecided about the exact design of the deck planking at the moment, but the margin board around the gunwhale and the top strake of the hull will be varnished sapele. That said, I actually used a piece of apple for the insert (just because I like it) and here it is glued in place with a very rough sketch of the final shape on it.

All the internal structure is going to be douglas fir, if only because I have plentiful offcuts from a small (but full scale) boat I built a couple of years ago. It is also easy to work, reasonably light and flexible. I made up some 10mm square pieces for the major deck beams as well as some temporary hull braces - the hull is quite flexible around the top until some structure is inserted.

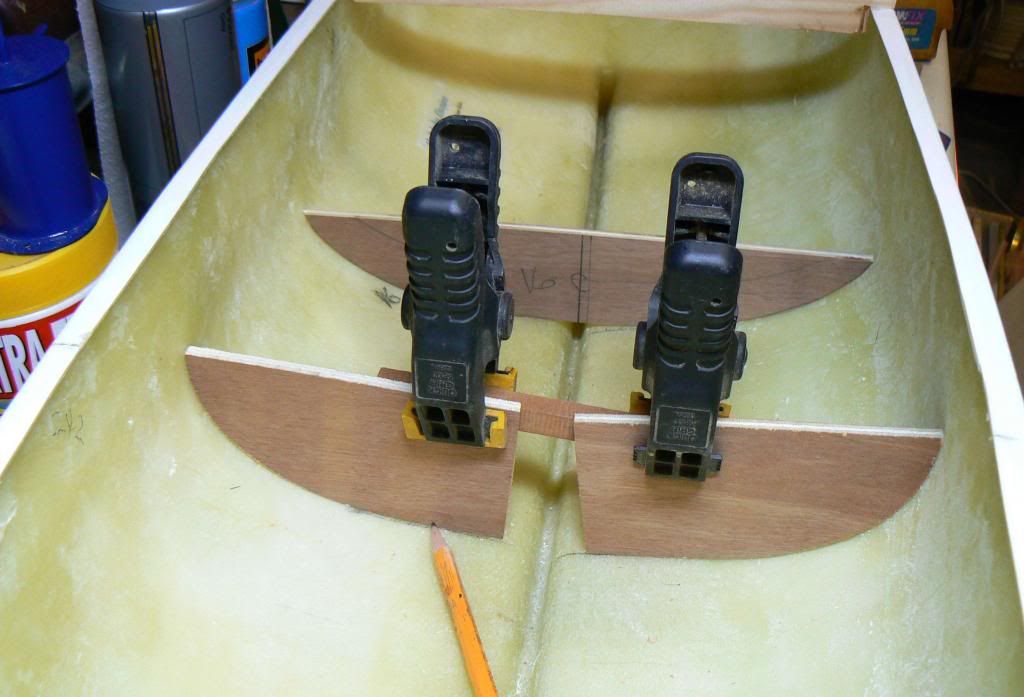

The first real structural parts to be put in place are the floors that will carry the steam plant. I need to get the position of that fixed before I finalise the details of the surrounding structure. Shaping the floors to fit the hull is fairly easy if you follow logical steps. I used some 6mm ply to make patterns, as follows. First, I marked on the hull where I wanted the floors to be, then I cut a piece of ply to roughly fit into one side of the hull at the first of these positions. Holding it in place, I spiled the shape of the hull onto this by running a pencil around the inside of the hull. Take the ply to the disc sander, sand to the pencil line and the piece should fit nicely. Of course, it doesn't, so have another go until you get it acceptable. Make a duplicate for the other side of the hull, then clamp the two pieces together - it is much easier to get the first pass with two halves rather than trying to do a full pattern straight off. Put the pattern back into the hull and check for fit -

Assuming you have a reasonable fit, copy the full pattern onto another piece of ply, cut that out and put into place. I also made sure that the top of the pattern was horizontal with a small spirit level, then spiled the full pattern one more time. You can see a finished pattern in the background of the picture above, and here are three complete ones -

These are much higher than I need the finished floors to be, and that leads me to my first question. The drawing supplied with the hull shows the steam plant mounted fairly high up in the hull. The hull form does not demand this - it is quite beamy and fairly flat-bottomed so my steam plant can sit quite low in the hull. Apart from stability issues, the illustrated installation means that the prop shaft has to be installed at quite a steep angle. The only benefit I can see is that the inboard end of the prop shaft is above the waterline. I know in full size this is not required, but do models normally require this because otherwise the tubes leak? (Perhaps I should have mentioned that I've never built a working model boat before

- oh, you'd guessed!) So can I place my plant low in the hull, make the prop shaft more horizontal and keep away from stability issues, or will I just gradually sink?

And my second question (already posed on the other thread but without any response yet) - in all other steam launches I have seen, the water tank to top up the boiler is a separate moulding or metal construction - and given that most are in the bow, they are not an easy shape to create. Is there any reason why I cannot simply create a tank within the hull by epoxying in two bulkheads and a floor? It seems much easier than trying to make or buy a weirdly shaped tank, but nobody (as far as I can see) does it that way. Any views?

Well that's it for now. It might be a while before the next episode as I plan to plank the inside of the hull to hide the surface of the moulding so I'll be producing dust with the saw and thickness sander for a little while. More douglas fir, and if I feel really keen some ash ribs as well. We'll see how it goes!

Greg

Author

Topic: Solent steam launch build log (Read 43070 times)

Author

Topic: Solent steam launch build log (Read 43070 times)