|

|

|

|

|

“DO THEY BOTH GO ROUND,

MISTER?” |

|

Scale-model designer Dave

Milbourn offers some insights into the various methods used for

controlling twin propellers. |

|

Dave's Definitive answer

for setting up Twin Electric Motor installations! |

There is no doubt that the

single-screw R/C model boat is the simplest form of the powered genre.

Quite apart from the added complications of building a multi-screw boat,

the modeller needs only to purchase, fit and maintain one of everything

e.g. motor, shaft, coupling, speed controller etc. If building an exact

replica of a twin-engined boat isn’t for you there’s no reason why you

shouldn’t adapt the model below the waterline to use a single prop

instead. Glynn Guest’s simple balsa-and-card models of warships are one of

the best examples of this approach to design, and their popularity

demonstrates that not everyone wants or needs to build more complex

models. This philosophy doesn’t stop there; I wonder how many modellers

have built a Huntsman or Perkasa without realising that the full-size

craft had respectively two and three props. |

If you balk at the idea of not having two props on a scale model of a

twin-prop boat then one approach is to fit a single motor which is geared

to two shafts/props. For a “performance” model this would have some

advantages, as geared drives are usually more efficient than direct

drives. One might alternatively fit two motors connected to the same speed

controller, although some care would be required to ensure that the motors

were evenly matched. For slower scale models, however, the use of two

independently controlled motors can greatly enhance manoeuvrability by

taking advantage of asymmetric thrust. Let’s consider first of all the

mechanics of how a boat turns. |

|

|

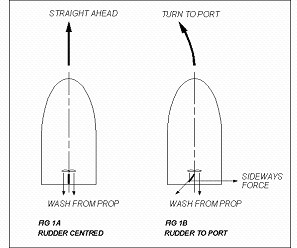

In Fig 1A, the rudder is centred and the propeller is pushing the water

straight back over it. The only thrust force acting on the model is in

line with its direction of travel so the boat will move straight ahead.

Fig 1B shows the rudder turned to port. Some of the wash from the prop is

now deflected “off course”, producing a sideways force on the rudder. We

now have two thrust forces acting on the model; one pushing it forward and

another tending to push the stern towards the starboard side. The result

is that the forward speed will drop very slightly and the boat will turn

to port. Quite how much the boat turns depends on the amount that the

rudder is deflected and the speed of the prop-wash over it. OK – so it

also depends on the size of the rudder but you’re not about to dive into

the water with a hacksaw and file to change that, are you? Dead

simple so far, so let’s double the number of rudders and props. |

|

|

|

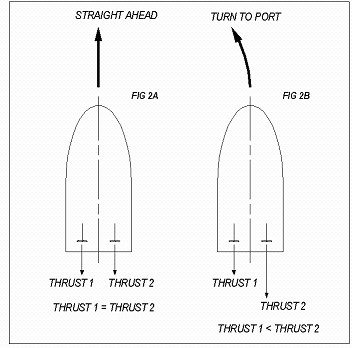

Fig 2A shows our twin-screw

model at full-ahead – assume the rudders are centred. So far it looks just

like Fig 1A but things are not as simple as they seem. The props are no

longer on the centre-line of the model so any thrust they produce will

also have a turning effect (or “moment”) about the boat’s vertical axis.

It’s only when the props are producing the same amount of thrust that

these turning forces are balanced out, and the model will travel straight

ahead. If you slow down one of the props (Fig 2B) the net effect will be

to turn the boat slowly towards the slower prop. If that sounds clumsy

then think of a rowing boat; if you pull harder on one of the oars then

the boat will turn away from that oar. It should be noted that these

forces are in play regardless of the position of the rudders. |

As I mentioned earlier, the rudders have a decreasing effect on the rate

of turn as the speed of the water flowing over them is reduced. This

explains why boats don’t steer as well when going astern, because the wash

from the props is moving away from the rudders instead of over them. Those

who can remember the first time they tried docking a model in a steering

competition will know how embarrassing this can be! The beginners’

technique seems to be to slam the rudder hard-over, stab the throttle and

pray you’ve got them both in the right direction. If you can harness the

asymmetric thrust effect from twin props then the rudders become almost

irrelevant for slow-speed manouvering. On full-size vessels this is

usually done by having the two throttles side-by-side on the same

binnacle. They can then be moved together for altering the speed of the

boat, or “split” for the sort of effect described above. We are not,

however, dealing with the big ‘uns here. |

|

|

|

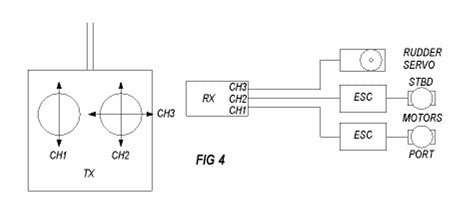

Fig 4 shows the R/C equivalent

of the controls available to a full-size vessel’s skipper. The LH stick

controls the electronic speed controller (ESC) for the port motor while

the RH stick controls the starboard one. Incidentally, it is usual for

twin props to be set-up as per Fig 3, with the starboard prop rotating

clockwise and the port anticlockwise when viewed from the rear. It is also

convention – at least among right-handed skippers – to use the lateral

movement of the RH stick to control the rudders. Many modellers replace

the ratchet on the LH stick with a self-centring spring, so that both

sticks return to neutral in both planes when you release them. Usually a

call to the distributor of your R/C gear will elicit the few components

necessary to do the job – often for little more than the cost of postage

(thanks, Amerang!) You will now have direct and fully independent control

over both motors, as well as being able to apply any amount of rudder

control desired. This independent control of the motors is often referred

to as “tank steering” because it mirrors the way a tank-driver controls

the tracks of his vehicle to steer it. It does have two drawbacks; you

will have spotted that it requires a 4 or 6 channel transmitter i.e. one

with two dual-axis sticks, and it demands an awful lot of practice and

concentration to make the model do what you want it to. If you’re the sort

of person who can pat the top of your head with one hand while rubbing

your tummy at the same time with the other, then tank-steering is probably

the ultimate in controlling your model boat. What about the rest of us,

though? |

|

|

|

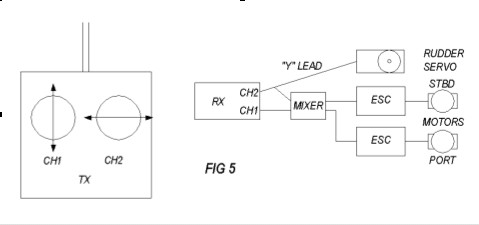

Fig 5 shows the installation

of a typical mixer unit. This is an electronic device which is fitted on

board the model and is connected to both the rudder and throttle outputs

from the receiver. It draws its power from the receiver pack and is

typically no larger than a receiver. Quite how it works is a mystery to me

– something to do with a microprocessor, I gather – but it senses signals

from both the throttle and steering outputs and automatically slows down

the motor on the inside of the turn dictated by the steering command.

There are two types of mixer available. One will go as far only as

stopping the inboard motor at “full rudder” (a 50% mix) whereas the other

will actually put the inboard motor into full reverse (100%). This latter

enables a model to spin round in its own length. In practical terms a

long, thin model such as a warship or submarine would be best suited by a

50% mixer, whereas tugs and other workboats would probably be better off

with the Full Monty job. Beware of earlier units, however. Some of them

actually worked against the rudder command when going astern so do

check before you part with any money. |

|

|

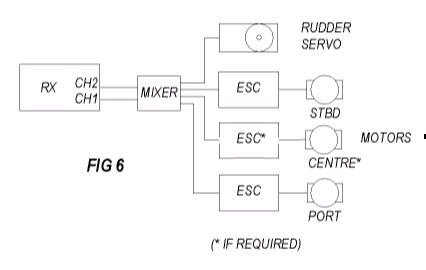

The ACTion Marine Mixer which I personally favour works correctly in both

forward and reverse, and it has a couple of useful features which you

might wish to note (See Fig 6). There is no need to buy and fit a Y-lead

here, as the mixer has a “straight-through” connection which enables you

to plug the rudder servo into the mixer itself. It also has a

straight-through (unmixed) output for use where a model has a third motor

installed along the keel-line and which doesn’t require mixing e.g. a

model warship. Contrary to popular mythology, you don’t need a university

degree to set up a mixer in your model. I have used both the Hunter

Systems and ACTion units and found that both worked fine if you follow

the detailed instructions closely, in the order given. It is useful if

you have a couple of spare servos to assist in the initial setting-up

procedure on the bench before the mixer is fitted into the model. It may

seem rather obvious but you should ensure that you use speed controllers

of the same type and current-rating and take care that the motors are as

near to identical in performance as you can reasonably find. This advice

applies equally to models fitted with “tank steering”. In respect of power

supplies, I have used separate packs for each motor/ESC in some models and

run both motors from the same battery in others. The latter seems to make

more sense as it side-steps the risk of one pack running down faster than

the other and mucking up your steering that way. The only slight

problem I have ever found was when one motor seemed to run up to

full-speed quicker than the other on the bench. By the time the model was

in the water, however, it was impossible to notice any effect on the

handling. |

Mixers have two main

advantages over tank-steering; there is no need to buy a 4 or 6 channel

radio to enjoy the benefits of controlling twin motors, and they do take

the pain out of stirring the sticks. As my friend Lawrie White says,

however, they will always mix the rudder and throttle commands

together irrespective of whether or not it is actually the most

appropriate command for the situation. You simply have to get to know how

your model responds to given commands. I understand that many modern

computer radios include the facility to program in a “mix” between any two

channels and also to adjust the amount of mix applied (e.g. 0% - 100%). I

don’t have one of these sets so I can’t advise you any further about them

– save to say that they are much more expensive than the

non-computer types, whereas an on-board mixer unit will cost you only

around £30 - £40, built and tested if you require it. |

So the BIG QUESTION is “which is best for my particular model?” I don’t

personally think that the model matters half as much as the

builder/skipper. I suspect those who have mastered the black art of

tank-steering would never dream of using a mixer, while those whose thumbs

don’t work like that are probably better off with one. I count myself

firmly in the latter group!!

(Article first published in

Model Boats magazine)

Many thanks to Dave Milbourn for digging this out for me and 'OCR ing' it

etc. - Martin, Mayhem

|

|

Back to Electrical Index

HOME |