|

HYDROSPEED - Graupner |

|

|

Running name

"The Hydro" Accessories required. Motor kit, speed control & batteries) + radio. |

|

|

|

|

|

|

|

|

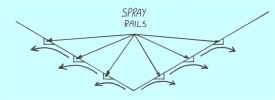

After relatively good success with the MFA PIRANHA, another electric boat was required to race against but one a little faster this time. I was now looking at all the different sports boat kits on the market and was having a hard time choosing one as there are quite a few on the market. Most seem to be made by foreign manufactures and constructed in ABS plastic. ABS "sports" kits may seem to be expensive for what they are, a few sheets of moulded plastic etc, but their standards of manufacture are very high and usually a lot of effort has gone into the design. Eventually my choice came down to two boats, the Graupner HYDROSPEED or the Kyosho CASABLANCA. I nearly bought a Kyosho CASABLANCA as it is very sleek looking catamaran with twin electric outboard motors, but due to it's price and conflicting reports that I had heard about it, I bought the slightly cheaper model, a Graupner HYDROSPEED. As it turns out the outboard motors on the Casablanca look much better than they ran! The Hydrospeed's hull design is 'shallow Vee' with spay rails that run the length of the hull that raise the hull up out of the water. Briefly, spray rails stop water riding up the sides of the hull by deflecting the water downward providing lift, thus rising the hull out of the water reducing drag.

|

|

|

"But

doesn't that mean that you only get half the thrust?" That's

what I said, but much higher propeller speeds are obtainable

because less of the propeller is in the water. I know that doesn't

make much sense but it had been explained several times to me and I

still don't fully understand it. It's something to do with the

speed that blade can pass through the water and if only one blade is

in the water, it doesn't pass through the wake made by the other

blade or blades and so can take a clean bite at undisturbed water.

For more information on surface drives, have a look at... All I know is that a surface drive propellers boats can go faster that a boat with a submerged drive for the same amount of engine power. I think I can here the howls of criticism already. Surface drive propellers are used on outboard engines, stern-drives and outdrives. You know what a outboard engine is, a sterndrive or strudder is a boat with a inboard engine and a drive system through the transom.

Graupner's Strudder MkI |

|

|

The great thing about this motor unit is that the motor doesn't need to be lined up with the shaft as the gears take care of that for you. The motor attached is a Graupner 7022, a 550 sized motor and of excellent quality, it can rev over 20,000 rpm and withstand 40 Amps (stall current) and still win a race! As the propeller is surface drive, normal propellers don't very well at all. Order a spare one or two propellers along with the universal joint (UJ) which is also non standard. This kit doesn't need any modification but I made a few to make for easy maintenance. Most of these modern prefabricated kits have been well thought out in nearly all the parts you'll need for completing the kit are made by the manufacture. This I think is a good idea because the amount of time I've wasted looking for or making parts for boats is nobodies business. True, the makers prices have to be seen to be believed but if you are not into making everything from scratch then you can be on the water in double quick time courtesy of the manufactures producing quick build boats. The kits

instructions are very clear and are good for the first time

modeller, a large full size plan is also included. The instructions

are translated from German to English and will provide a free

giggle while building. The instructions

do tell you everything you need to know but

I'll provide you with a few extra points to watch out

for. |

|

|

STABILIT EXPRESS Due to the high

price of Stabilit glue , I tend to use thick super-glue for nearly

everything apart from high stress areas such as prop tube exit and around

the transom. |

|

|

BUILDING SITE With all parts cut out, glue the radio tray to the underside of the deck and leave to set. The plans are very clear on how to make the hull to deck joint but just you wait till you have to do it for yourself!! When you come to fit the deck, everything will try to move it self out of place and generally be as difficult as possible. Plan how you are going to hold the joint in place while setting and have several practise runs. The plan show

the joint glued from the outside only but it would be better to get some

Stabilit under the joint as well. You could try Sellotaping the deck

down or 'tacking' the deck down with tiny spots of Superglue and

then seal the joint with Stabilit.

|

|

|

RUNNING GEAR and ELECTRICS Talking about the main shaft, drill a hole in the tube and fit a the plastic shaft oilier but it's difficult to use in practice when the boat is complete. I fitted a brass oiling tube 1/8 OD about 10mm from the front bearing, just behind the gearbox housing and curved it around the motor and cut it of level with the top of the motor. Stuff tissue paper in the ends of the shaft to prevent blockage and soft solder on the oil tube building it up to form a strong fillet.

When fitting

the shaft, ensure that

there is lots of Stabilit around and under the shaft at the transom

because it will soon be covered by the radio box floor. Be

careful when fitting the strudder unit as the position marks on the

hull aren't quite right so make correct marks taken from the

plans. The control rods from the servo to the strudder took some

real bending to get right. The shape on plans didn't want to

work at all, so be prepared to spend a whole evening on just

these linkages alone. On a later boat,

a Graupner Key West, these links are made from short lengths of

Bowden cable and are a much better idea. Use your wife's (or husband's?!)

nail polish to lock in the grub screws. |

|

|

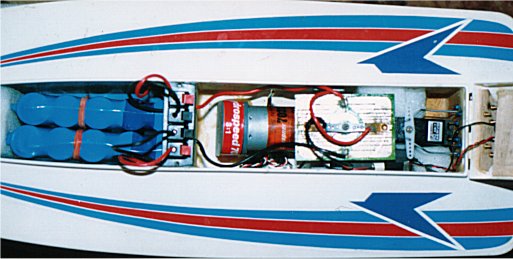

SPEED CONTROL The plans do not include a water tight radio box which caused me some concern during building but in practice it's quite difficult to soak the radio gear anyway (see conclusion). I don't like the sound of all-or-nothing speed control as you get with micro switches, so I modified the internal layout to suit an 8 Amp 'Bob's' board speed controller. Clean both the top of the servo and bottom of the control board with meths or thinners and stick the board down with double sided tape or hot glue. The output arm of the servo needs to be modified to fit the wiper contacts but this is covered in the instructions with the 'Bob's' board. Lubricate the wiper contacts with silicon grease. Because of using a Bob's board and the addition of a bulkhead the radio layout was slightly altered to fit. The servos were screwed to wooden rails that were in turn fixed to the radio box walls.

A bulkhead of 3mm ply was fitted behind the motor to prevent water splashing all around the boat. I left room in front of the gearbox to allow the cover to be removed for servicing but trying to get it back on again in situ is next to impossible. I was still using the battery sets I made up for the PIRANHA and so I fitted the same speaker type speaker wire connector for the battery leads. A piece of foam holds the two battery packs in place.

|

|

|

THE TOP |

|

|

FINISH |

|

|

SAILING I set up the tilt of the strudder to run parallel to the hull keel and float tested the completed boat in the specially built heated fibreglass test tank in the bathroom, she floated level and true. I was chased from the test area when I revved up the motor as this sent a spray of water up the bathroom walls! Down at the lake with 'all engines ahead one third at the helm' the HYDROSPEED whirred like a food mixer and gurgled and burped until the propeller got to grips with the water. She has a good rate of acceleration and a rooster tail of spray is thrown into the air by the surface piercing prop. All was well she had no horrible quirks and did what she was told. 'All ahead flank', at full speed the whirring increased relative to the speed. She is not quick but quite fast, it takes a few seconds for the propeller to grip the water from a standstill so a steady acceleration is needed from the throttle for a quick takeoff. The roster tail of spray from the propeller does look really good when it catches the sunlight as you cross the lake.

|

|

|

CONCLUSIONS Again I had many months of running with this boat before selling it to a friend, Hi! Dave. He thought it could go faster after his first trial run. Out came the two 6v packs and in went two 7.2v car racing packs. Still wanting more speed from the boat, out came the three-to-one gearing and in went a two-to-one gear set. Now the boat can keep up with some of the IC boats all be it for a short while. It has since suffered a motor burn out due to a weed plant sabotage.

|

|

|

LESSONS LEARNED |

|

|

MODIFICATION POSSIBLE

FINAL SPECIFICATION

|

|

|

PERSONAL RATINGS |

(out of 10) 6 (All ABS kits are on the dear side) 9 (The ABS is moulded to high standard) 9 (Does just what makers say it will do) 8 (ABS takes a little getting used to) 8 (Comes with nice decals, no painting) 8 (Fast, very stable) |

|

Coming up.... Well all of

this is just my opinion, but what do I know! |

|

|

|

|

|

From left to right & Top to Bottom.

|

|